How do I determine which type of accumulator is needed for my application?

Q: How do I determine which type of accumulator is needed for my application?

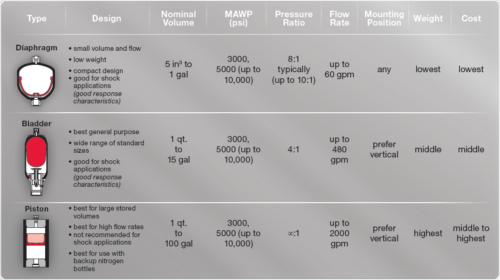

A: There is a general comparison chart (see below) which is also located in the Overview section of the Accumulator catalog which is located at Catalogs > Complete catalog which compares and contrasts the 3 main types of accumulators (bladder, diaphragm and piston) to various parameters.

The selection consideration for these 3 types of accumulators are:

- Application Type (energy storage, shock absorbptino or pulsation damening), see Application Examples section of the Accumulator catalog

- System pressure, maximum and minimun

- Required system fluid volume

- Ambient temperatures

- Fluid-to-elastomer compatability

- Flow rate

- Pressure Ratio(max. pressure / precharge pressure)

- Installation envelope and mounting position

This chart can be used to determine which accumulator type best fits certain applications or system requirements. Please contact Product Management to verify that the proper accumulator has been selected.

How does an accumulator work?

Q: How does an accumulator work?

A: A hydro-pneumatic accumulator stores hydraulic energy in a manner similar to how a car battery stores electrical energy. It is a pressure vessel that is comprised of a membrane or piston that contains a pressurized inert gas (typically nitrogen) and is connected to a fluid system. The gas pressure of the nitrogen is called the ”precharge pressure”. As the system pressure exceeds the precharge pressure, the nitrogen gas will begin to compress and decrease in volume allowing fluid to enter the accumulator. As the fluid system reaches its maximum pressure, the maximum amount of fluid will be contained inside the accumulator for a given pressure range and the nitrogen gas is compressed to the smallest possible gas volume. The accumulator is now able to supply fluid to the hydraulic system allowing it to do work. This is accomplished by the system pressure decreasing which, in turn, causes the nitrogen gas to expand displacing fluid from the accumulator into the hydraulic system under pressure.

How much fluid volume can an accumulator deliver to a fluid system?

Q: How much fluid volume can an accumulator deliver to a fluid system?

A: The amount of fluid volume that an accumulator can deliver is application dependent. The following parameters are minimally required in order to determine fluid volume and/or accumulator size:

Precharge pressure (P0)

Maximum system working pressure (P2)

Minimum system working pressure (P1)

Effective Gas Volume (V0) or Usable Fluid Volume (ΔV)

Please contact Product Management to assist in this effort.

Why is my 4L bladder accumulator not providing 4L of oil to the system?

Q: Why is my 4L bladder accumulator not providing 4L of oil to the system?

A: The 4L size refers to the total nominal gas volume not the fluid volume. The volume of fluid that an accumulator provides for a particular application is dependent on the differential pressure in the system.

What does charging and discharging of an accumulator mean?

Q: What does charging and discharging of an accumulator mean?

A: Charging an accumulator is when the system pressure increases and fluid flows into the accumulator, compressing the nitrogen gas in the accumulator. Discharging an accumulator is when the system pressure decreases allowing the nitrogen gas in the accumulator to expand, in turn, causing fluid to flow out of the accumulator.

What is pressure ratio?

Q: What is pressure ratio?

A: The Pressure Ratio is defined as: P2/Po expressed as P2:Po Or System Max Pressure / Pre-Charge.

Why is pressure ratio important?

Q: Why is pressure ratio important?

A: The design and physical construction of bladder and diaphragm accumulators have limits on the maximum pressure ratios that they can safely operate in. Exceeding those limits can potentially result in damage to the bladder or diaphragm. The piston accumulator does not have an elastomer membrane that can be subject to damage and thus allows for a higher pressure ratio than bladders or diaphragms. The recommended maximum pressure ratios for each accumulator type are listed below:

Bladder accumulators – the maximum Pressure Ratio is 4:1

Diaphragm accumulators – the maximum Pressure Ratio is 8:1 (certain models are 10:1 and others may be 4:1)

Piston Accumulators – the maximum Pressure Ratio can be ∞:1

What are the recommended precharge pressures?

HYDAC recommends the following:

For energy storage: Po = 0.9 x P1, (P1 = minimum working pressure)

For shock absorption: Po = (0.6 to 0.9) x Pm, (Pm = median working pressure at free flow)

For pulsation dampening: Po = (0.6 to 0.8) x Pm, (Pm = median working pressure)

Can accumulators be shipped with a precharge?

HYDAC has a DOT exemption for shipping hazardous goods which allows us to ship precharged accumulators up to 70% of the vessel design pressure via ground transportation only. You can forward the precharged accumulators to another location under our DOT exemption so long as you leave the container intact.

How often must I check gas precharge pressure on my accumulator?

Gas precharge pressure should be checked at least once during the first week of operation. If there is no loss of gas precharge pressure, it should be rechecked in 3 to 4 months. Thereafter, it should be checked at least once a year.

Is there a way to monitor gas pressure?

Yes, we recommend doing this via a permanent gauging block. The gauging block mounts directly on top of the gas valve and is available for both Version 1 and Version 4 gas valves. The permanent gauging block can remain in position during both charging and operational use of the accumulator.

What is gas permeation and how much should I expect from my accumulator?

Gas permeation is the penetration of a gas (i.e. Nitrogen) through a solid. With regards to accumulators, this is the permeation of the gas though the bladder or membrane (diaphragm). In general, the industry standard for gas loss (permeation rate) for bladders and diaphragms is ~10% per year. However, HYDAC’s permeation rates are typically better meaning less times that you have to add gas to the accumulator in order to maintain the precharge pressure.

Is an accumulator shell repairable?

No, the whole shell must be replaced.

Can I affix a lifting eye/lug to the accumulator for positioning purposes?

Lifting bladder accumulators with a lifting eye is not recommended for HYDAC SB Series bladder accumulators as this puts a lot of stress on the gas valve which is vulcanized to the bladder itself. We recommend using a choke sling or harness.

Do you have an MSDS sheet for your accumulators?

No, an MSDS sheet is not required for HYDAC accumulators. However, if an accumulator has a precharge an MSDS sheet might be required for the Nitrogen gas. HYDAC has these readily available or they can be obtained from your gas supplier.

Do you test your accumulators? If so, by what means?

Yes, our accumulator shells are hydro tested to meet ASME requirements. There are no ASME requirements to test the component parts such as the bladder or fluid port. Additional testing can be completed based on your specific requirements but this will likely add cost.

Are there limitations on accumulator installation positions?

No, however, accumulator life expectancy and performance can be affected by mounting positions. Only diaphragm style accumulators are designed to be mounted in any orientation. The preferred mounting position for a bladder style accumulator is vertical, however, it can be mounted horizontally. A bladder accumulator mounted horizontally will contain residual oil that will not fully evacuate for the application. Application information should be reviewed by Product Management prior to mounting a bladder accumulator horizontally. A piston style accumulator can also be mounted horizontally, however, seal life may be compromised due to friction and fluid cleanliness.

How do you store a bladder accumulator?

If the period of storage up until commissioning is no longer than 3 months, it is sufficient for the pre-charged accumulator, which is moistened on the inside with hydraulic fluid, to be stored in a cool, dry place, protected from direct sunlight. The accumulator can be stored in any position. To prevent contamination from entering the accumulator, make sure that the hydraulic connection is plugged. If the accumulator is to be stored for longer than 3 months, discharge the pre-charge down to 2 bar to prevent the bladder from becoming deformed. When commissioning the accumulator, allow the hydraulic fluid to flow in slowly in order to protect the bladder. If the accumulator is intended to be stored for longer than one year, it is advisable to disassemble it and store the accumulator and bladder separately.

What is the life expectancy of my accumulator?

The life expectancy of an accumulator is dependent upon many factors such as the number of cycles, temperature and pressure ratio. A bladder or piston style accumulator can be kept in use for 10-20 years so long as proper routine maintenance occurs (i.e. occasionally replacing the bladder or seals and checking precharge pressure). HYDAC offers bladder and seal repair kits which are readily available in most sizes.

What bladder material do I need?

Bladder selection is based on fluid and temperature compatibility. Please refer to the chart under the Bladder Compound section under Model Code of the catalog located at: Catalogs > Accumulators to get the main catalog or just type bladder accumulator at the search up top. If still unsure of bladder selection, please contact Product Management.

What bladder repair kit and/or seal kit do I need for my accumulator?

If you know the size in liters, bladder material, and accumulator style (SB330 (3000 PSI) or SB600 (6000 PSI)), then selecting the correct bladder repair and/or seal kit becomes routine. If you are unsure of the bladder material then the fluid being utilized must be provided. For bladder-to-fluid compatibility information, please see the previous FAQ above. With the information known, you can select the proper repair kit and/or seal kit from our catalog located at: Catalogs > Select Accumulators catalog from the list, you can also search for spare Parts, Seal Kits & Tools from the search bar at the top. For repair kits and seal kits other than Buna N, and for sizes and types not listed please contact HYDAC.

Do I have to order a complete repair kit or can I just order the part I need from the repair kit?

No, you do not have to order a complete repair kit as individual parts can be ordered separately. The parts that comprise a repair kit can be found in the catalog at: Catalogs > select Accumulators catalogs or search Spare Parts, Seal Kits & Tools from the search bar at the top.

Do you sell seals separately?

Yes. Seal kits for bladder & piston accumulators and safety & shut-off blocks are available from Customer Service.

Does HYDAC still offer accumulators with ”A” designated as the country code?

No, this has been directly replaced with models that have the ”U” designated as the country code. The ”U” took the place of the ”A” in the model code to better communicate the fact that this is a PED (Pressure Equipment Directive) certified unit specifically designed for use in Europe.

Do I have an SB330 (3000 PSI) or SB600 (5000 PSI) model accumulator?

If the model code or part number cannot be readily located on the unit or any associated paperwork, you must inspect the gas valve stem on the accumulator itself. If the diameter of the gas valve stem at the point where it comes out of the shell is 7/8” (22 mm) then it is a SB330. If it is 2” (50 mm) then it is a SB600.

How do I replace my poppet valve?

The poppet valve is built into the fluid port and is not a replaceable part. You would need to replace the entire fluid port.

I have a 50L bladder accumulator, is this model still available for purchase?

We no longer actively market the 50L bladder accumulator in the US. The 50L is still available out of HYDAC Germany but lead times can be as long as 14 weeks. However, HYDAC USA now offers the 54L version as an equivalent with much shorter lead times. We still continue to offer the 50L bladder repair kits out of the US.

Can a diaphragm accumulator be repaired?

Our standard welded design diaphragm accumulators are designed to be discarded and cannot be repaired. We do offer threaded repairable diaphragm accumulators for many applications. However, the cost for spare parts and repair time for a threaded version might make it less practical than just replacing a welded version.

Can I purchase a diaphragm accumulator with an ”E2” style gas valve?

The ”E2” style gas valve is not very common and thus typically requires a minimum purchase quantity of 200 pieces.

What charging & gauging kit do I need?

For accumulators with metric style M28 x 1.5 gas valves (HYDAC Gas Valve Version 1), you will need an FPK Kit. For accumulators with schrader style ISO 4570 (VG8) gas valves (HYDAC Gas Valve Version 4), you will need an FPS Kit. For charging of both style gas valves, you will need an FPK Kit with an A3 (FPK/SB) Adapter. For accumulators with 2-piece style gas valves, you will need an FPO Kit.

Can I replace just the head assembly on my FPS & FPK charging and gauging kits?

Yes, the corresponding charging unit head assembly part numbers are listed below. Please note the pressure gauge does NOT come with the replacement head assembly. If a replacement gauge is needed it must be ordered separately (see FAQ below for a list of available gauge P/Ns and connection info).

FPS Charging Unit Body: P/N 379083 FPK Charging Unit Body: P/N 379084

What is the pressure gauge connection on a standard permanent gauging block and various charging & gauging units? What are the pressure gauge part numbers per product?

See list below.

PERM GAUGING BLOCK VER 1 or 4 (Bottom Repairable): G1/4 BSPP connection (Back Mounted Gauge)

| PART # | DESCRIPTION / MODEL CODE |

| 606741 | PRESSURE GAUGE 60 BAR/0 to 850 PSI |

| 606743 | PRESSURE GAUGE 100 BAR/0 to 1450PSI |

| 606745 | PRESSURE GAUGE 160 BAR/0 to 2300PSI |

| 606747 | PRESSURE GAUGE 250 BAR/0 to 3600PSI |

| 606749 | PRESSURE GAUGE 400 BAR/0 to 5800PSI |

FPS & FPK CHARGING & GAUGING UNITS: G1/8 BSPP connection (Back Mounted Gauge)

| PART # | DESCRIPTION / MODEL CODE |

| 606759 | PRESSURE GAUGE E63/10/0 to 145 PSI |

| 606760 | PRESSURE GAUGE E63/25/0 to 350 PSI |

| 606761 | PRESSURE GAUGE E63/100/0 to 1400PSI |

| 606762 | PRESSURE GAUGE E63/250/0 to3600PSI |

| 606763 | PRESSURE GAUGE E63/400/0 to 5800PSI |

FPO CHARGING & GAUGING UNIT: G1/4 NPT connection (Bottom Mounted Gauge)

| PART # | DESCRIPTION / MODEL CODE |

| 2701622 | PRESSURE GAUGE 3000 PSI BOTTOM MOUNT(FP0) |

If my nitrogen gas bottle has a pressure reducer/regulator connected to it, what adapter will I need in order for it to work with a charging & gauging unit?

For domestic use only, each charging & gauging kit should come with a G4 or G4.1 adapter that would typically connect directly to your CGA 580 gas bottle (3000 PSI) or CGA 680 gas bottle (5000 PSI) respectively. However, with a pressure regulator connected to the nitrogen gas bottle, an adapter is required to connect to the G4 or G4.1 hose connection. See image below for proper adapter selection. We also offer various G adapters for non-domestic usage which can be found in the catalog at: Catalogs > selecting Accumulators from the list or searching Adapters under Charging & Gauging Units from the search bar.

Can I buy an FPU charging kit?

Yes, these FPU charging kits are manufactured in Germany and typically have a 10-12 week lead time. However, the FPU charging kit can be directly replaced with our FPK charging kit saving you on both price and delivery. The FPU-1 kit is basically an FPK charging and gauging kit with an ”A” adapter and a ”G” adapter included. Most FPK charging kits are kept in stock in Bethlehem, PA.

Are charging instructions available?

Yes, they are located on our website at: www.hydac-na.com select Accumulators for the catalog or search FPK/FPS Series from our search bar at the top.

Why is there an allen wrench in my FPK charging kit?

The allen wrench should be used to initially break the gas valve seal prior to installing the FPK charging unit. DO NOT USE THE CHARGING UNIT ITSELF TO BREAK THE SEAL AS INTERNAL COMPONENTS WILL BREAK REQUIRING COMPLETE REPLACEMENT OF THE FPK. Please consult the ”Maintenance” section of Charging & Gauging Kits on our website

How do I install a permanent gauging block?

Instructions are located on our website at: Catalogs, select Accumulators catalog or search Permanent Gauging Blocks from the search bar up top. Please pay special attention to the gas core removal section.

Can I replace an SAF20M12…with an SAF20M16…?

Yes, the only difference between the two blocks is the seal material. The block with the ”M12” uses Buna N seals and the block with the ”M16” uses Fluoro-elastomer seals. We build our safety blocks in Bethlehem, PA utilizing Fluoro-elastomer seals and our German manufacturing uses Buna N seals.

Are SAB blocks still available?

No, the SAB block has been replaced by our model SAF block. It is functionally equivalent but not dimensionally equivalent. The pressure relief valve design was modified making it so that the old & new relief valves are no longer interchangeable.

Can I buy direct from HYDAC?

HYDAC works through a network of distributors. This list of distributors can be found on our website at: Distributor

Where can I find the ASPlight accumulator sizing program?

ASPlight can be downloaded from our website at: Software > select Accumulators from the list > select Accumulator Sizing Software from accordion.